Product Advantage

1. Integrated design of cutter and mandrel.

2. Fieldbus controller, with fast reaction speed and good synchronism.

3. Faster conversion speed of left and right hand spring.

4. Computer can automatically detect the temperature of motor and slow down its running speed to protect motor from overheating.

5. Computer can automatically decelerate according to the timing when probe should be used.

6. Prodution rate can be increased or decreased at any time of operation.

7. Max speed reaches 1000pcs/min, absolutely a nice equipment for small coil springs.

Technical Parameters

| Model: | XD-608 |

| Wire diameter: | 0.1-0.8mm |

| O.D: | ¢25mm |

| Production Rate: | 1000pcs/min |

| Feed Length: | unlimited |

| Wire Feed: | 0.75kw |

| Cutter: | 0.4kw*2 |

| OD Axis: | 0.4kw |

| Pitch: | 0.4kw |

| Arbor back-and-forth: | 0.4kw |

| Monitor Display: | Chinese/English |

| Max. Value: | 99999.99mm |

| Min.Value: | 0.02mm |

| Memory: |

150 Program Max 999 Lines for each program |

| Machine Dimension: | 90*70*135cm |

| Machine Weight: | 500kgs |

| Power: | 220v 3p 50/60h |

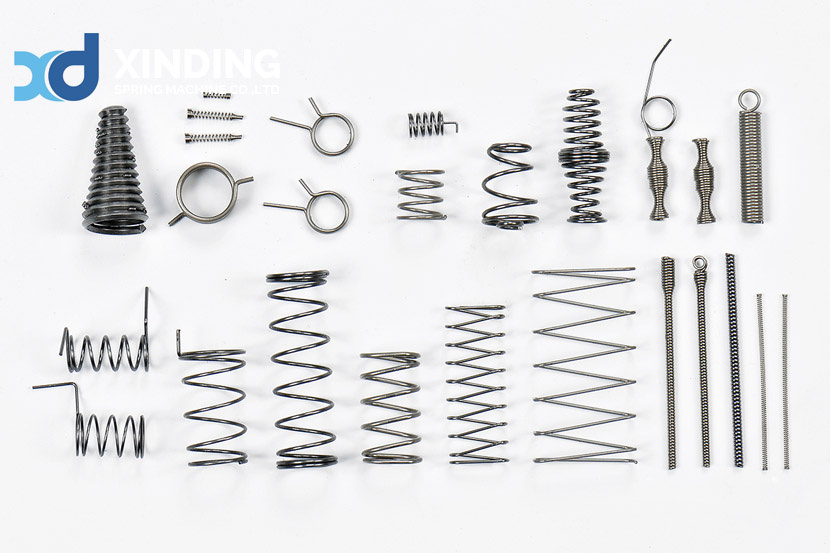

Sample Display

This CNC spring machine produce various ultra-precision irregular springs, compression springs, pulling springs, dual-torsion spring, flat line(spiral power spring)and line molding spring etc.

Video

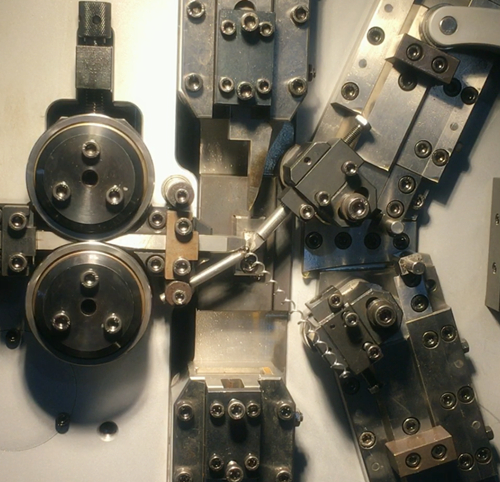

Product Details

1. Use servo control system to save energy 30-50 %.

2. repeatable positioning accuracy up to±0.01mm.

3. Low failure rate,automatic alarm and fault indication,one-button reset function.

4. Adopting an integral frame structure, high strength, low distortion and durability.

5. Innovative design of great flexibility.

6. Patented and innovative time-line-basis spring program software.

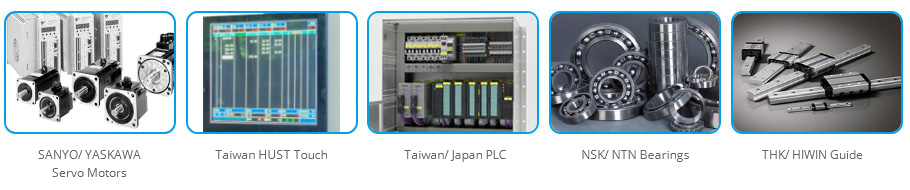

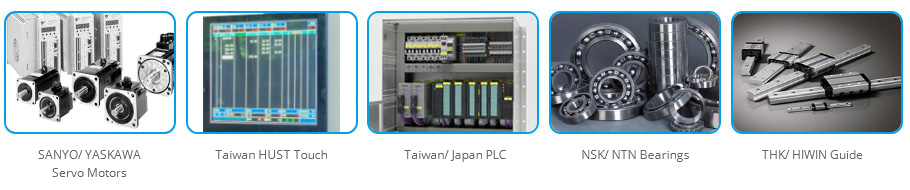

Use of famous brand components, ensures the stability of spring forming control system.

2. repeatable positioning accuracy up to±0.01mm.

3. Low failure rate,automatic alarm and fault indication,one-button reset function.

4. Adopting an integral frame structure, high strength, low distortion and durability.

5. Innovative design of great flexibility.

6. Patented and innovative time-line-basis spring program software.

Use of famous brand components, ensures the stability of spring forming control system.

Manufacturability

Service Clients

Certifications

Success Cases

English

English

Español

Español

Pусский

Pусский

简体中文

简体中文