Product Advantage

it aims to save you as much manual work as it can, unlike the traditional two axis spring coiler, most of the adjustment work are able to finished just on computer panel, cutting, pitch adjustment, spring outside diameter control, mandrel positioning, all can be done by just pressing computer key. the machine will save operator 50% of manual work compared to two axis model.

1. Mandrel is able to move back and forth, up and down.

2. Field-bus controller, with fast reaction speed and good synchronization.

3. Faster changeover speed of left and right hand spring.

4. Computer USB interface, operator can upload technical data.

5. Max speed reaches 1000 pcs/min, absolutely a nice equipment for small coil springs. compared with two axis spring coiler, much faster in operation and set up speed.

7. Optional safey door and spring length gauge available.

Technical Parameters

| 1.Model: | XD-808 |

| 2.Wire Diameter: | 0.1-0.8mm |

| 3.O.D: | ¢25mm |

| 4.Production Rate: | 1000pcs/min |

| 5.Feed Length: | unlimited |

| 6.Wire Feed: | 0.75kw |

| 7.Cutter: | 0.4kw*2 |

| 8.OD Axis: | 0.4kw*2 |

| 9.Pitch: | 0.4kw |

| 10.Arbor back-and-forth: | 0.4kw |

|

11.Arbor up-and-down: |

0.4kw |

| 12.Monitor Display: | Chinese/English |

| 13.Max. Value: | 99999.99mm |

| 14.Min.Value: | 0.02mm |

| 15.Memory: | 150 Program Max 999 Lines for each program |

| 16.Machine Dimension: | 90*70*135cm |

| 17.Machine Weight: | 550kgs |

| 18.Power: | 220v 3p 50/60hz |

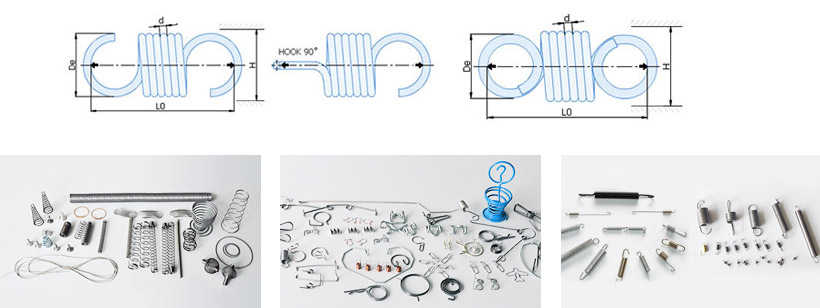

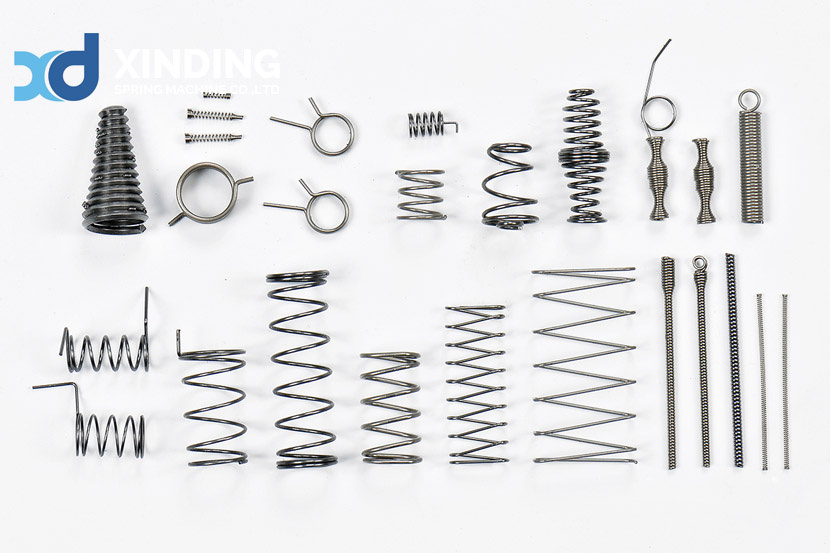

Sample Display

Video

Product Details

2. repeatable positioning accuracy up to±0.01mm.

3. Low failure rate,automatic alarm and fault indication,one-button reset function.

4. Adopting an integral frame structure, high strength, low distortion and durability.

5. Innovative design of great flexibility.

6. Patented and innovative time-line-basis spring program software.

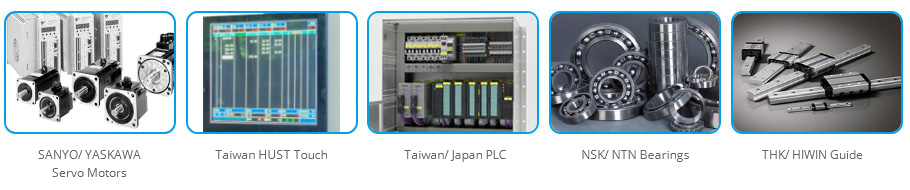

Use of famous brand components, ensures the stability of spring forming control system.

Manufacturability

Service Clients

Certifications

Success Cases

English

English

Español

Español

Pусский

Pусский

简体中文

简体中文