Details:

1. Servo motion system and servo drive controlled.

2. 5.7" control panel ,easy to operate.

3. Cam move both clockwise and anti –clockwise, wire feed length can be changed while running the machine.

4. Computer automatically detect temperature of the motor and slow down running speed to protect the motor from overheating.

5. Computer automatically decelerate when the probe should be used.

6. Prodution speed can be increased or decreased during running the machine.

7. Optional accessories: Torsion device, oil seal device, pneumatic sensor device, length gauge.

Product Range:

This compression spring machine make various types of compression springs, wire coil, oil seal springs, battery springs, taper springs, double-taper springs, safe springs, clip spring as well as various simple wire forms.

Technical Parameter:

| Model: | XD-216 |

| Wire diameter: | φ0.15~1.6 mm |

| Axes: | 2-3 axes |

| Maximum Outside Diameter: | 45mm |

| Maximum Feeding Length: | unlimited |

| Maximum Manufacture Speed: | 300pcs/min |

| Feed Speed: | 1550m/min |

| Memory Number: | 1000pcs |

| Wire Feed Servo Motor: | 2.7kw |

| Cam Servo Motor: | 2.7kw |

| Power AC: | 3-Phase 380V |

| Dimension(L*D*H): | 900X850X1600MM |

| Wooden Case Dimensions: | 1100x1100x1600mm |

| Machine Weight: | 800kg |

| Gross Weight: | 850kg |

Sample Display

Video

Product Details

2. repeatable positioning accuracy up to±0.01mm.

3. Low failure rate,automatic alarm and fault indication,one-button reset function.

4. Adopting an integral frame structure, high strength, low distortion and durability.

5. Innovative design of great flexibility.

6. Patented and innovative time-line-basis spring program software.

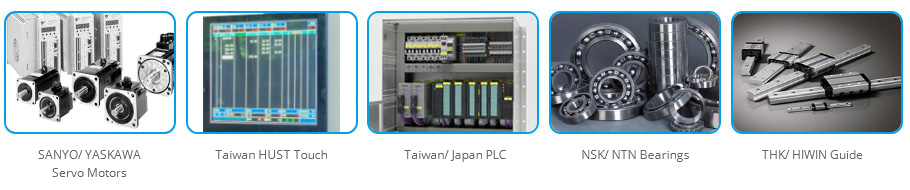

Use of famous brand components, ensures the stability of spring forming control system.

Manufacturability

Certifications

Success Cases

English

English

Español

Español

Pусский

Pусский

简体中文

简体中文