CNC20 Spring Machine Advantage

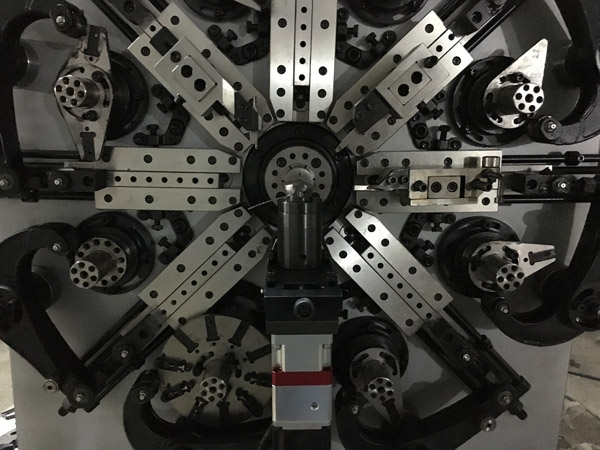

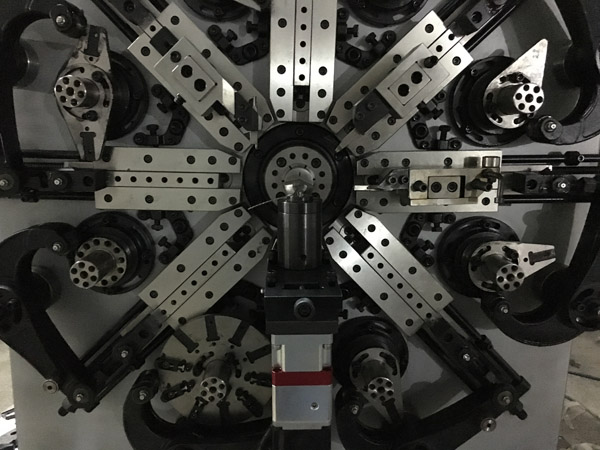

1. XD-CNC20 spring machine consists of cam axis, wire feeding axis, rotation core and rolling axis. mechanical part has eight sets of sliding blocks.

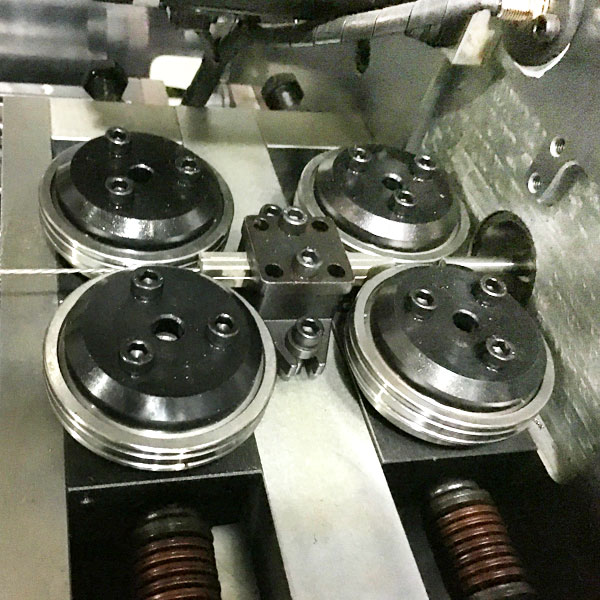

2. Computerized cam rotation system can be set from 0.1-359.9°, every two wire feeding wheels constitutes of one group, totally two groups.

3. XD-CNC20 cnc spring machine is equipped with Xinding spring machine controller. The controller system can save 1000 file numbers. Axis location, feeding data, production speed and production output are displayed on the screen. The program data can be set and changed easily.

2. Computerized cam rotation system can be set from 0.1-359.9°, every two wire feeding wheels constitutes of one group, totally two groups.

3. XD-CNC20 cnc spring machine is equipped with Xinding spring machine controller. The controller system can save 1000 file numbers. Axis location, feeding data, production speed and production output are displayed on the screen. The program data can be set and changed easily.

Technical Parameters

| Model: |

XD-CNC20 |

|

Wire diameter: |

φ0.3~2.3 mm |

|

Axes: |

3 axes |

|

Maximum Outside Diameter: |

40mm |

|

Maximum Feeding Length: |

unlimited |

|

Maximum Manufacture Speed: |

100pcs/min |

|

Feed Speed: |

200m/min |

|

Memory Number: |

1000PCS |

|

Wire Feed Servo Motor: |

2.7 KW |

|

Cam Servo Motor: |

2.7 KW |

|

Quin Servo Motor: |

0.75 KW |

|

Power AC: |

220V 3P 50/60Hz |

|

Dimensions (L*D*H): |

1400X550X1600MM |

|

Wooden Case Dimensions: |

1600x600x1700mm |

|

Machine Weight: |

900Kg |

|

Gross Weight: |

950Kg |

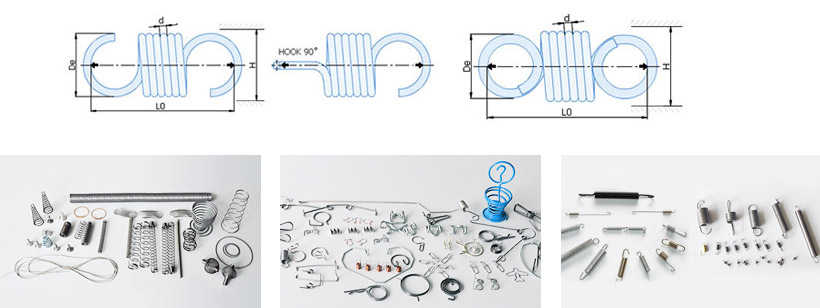

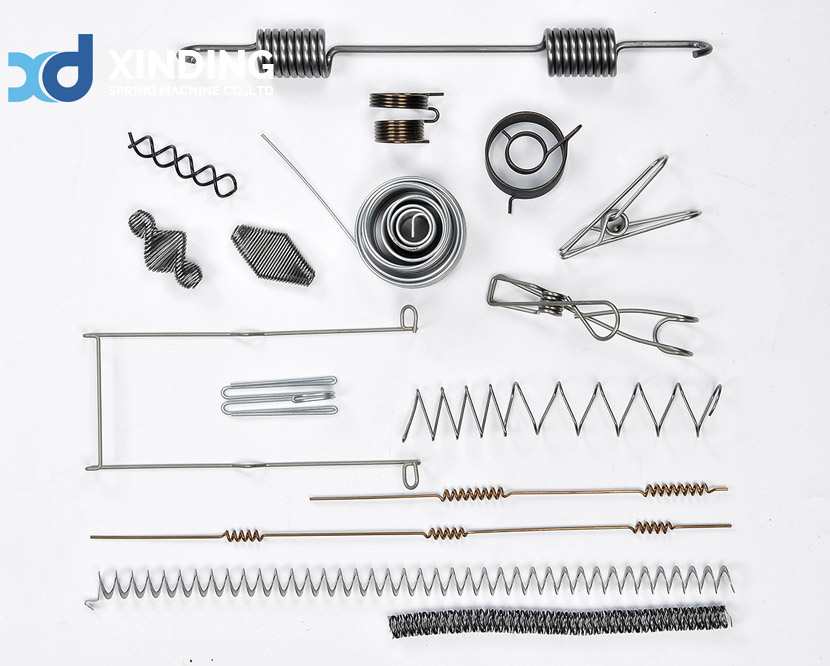

Sample Display

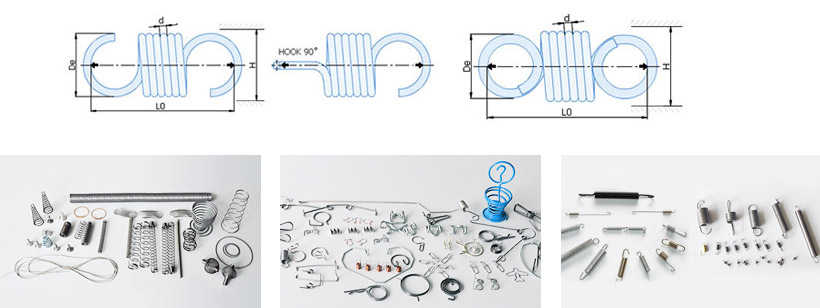

This CNC spring machine produce various ultra-precision irregular springs, compression springs, pulling springs, dual-torsion spring, flat line(spiral power spring)and line molding spring etc.

Video

Product Details

1. Use servo control system to save energy 30-50 %.

2. repeatable positioning accuracy up to±0.01mm.

3. Low failure rate,automatic alarm and fault indication,one-button reset function.

4. Adopting an integral frame structure, high strength, low distortion and durability.

5. Innovative design of great flexibility.

6. Patented and innovative time-line-basis spring program software.

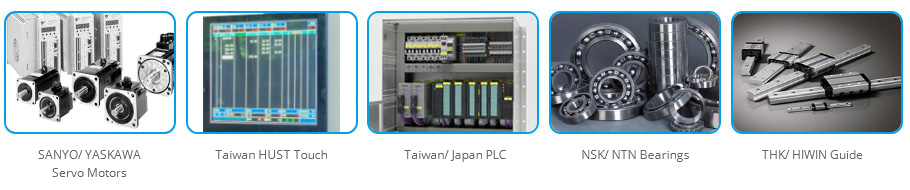

Use of famous brand components, ensures the stability of spring forming control system.

2. repeatable positioning accuracy up to±0.01mm.

3. Low failure rate,automatic alarm and fault indication,one-button reset function.

4. Adopting an integral frame structure, high strength, low distortion and durability.

5. Innovative design of great flexibility.

6. Patented and innovative time-line-basis spring program software.

Use of famous brand components, ensures the stability of spring forming control system.

Manufacturability

Service Clients

Certifications

Success Cases

+86-769-85560018

English

English

Español

Español

Pусский

Pусский

简体中文

简体中文